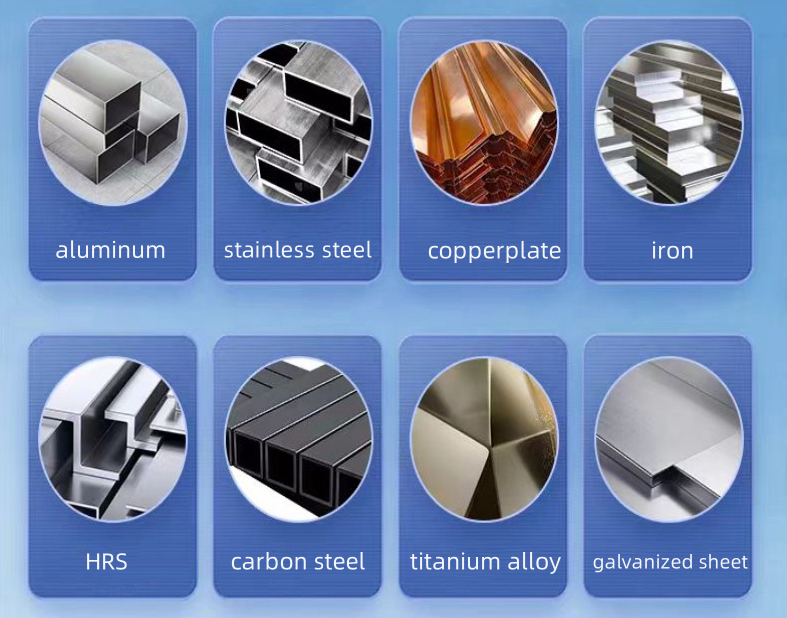

1. Stainless steel

Stainless steel has a high coefficient of thermal expansion, and it is prone to overheating during welding. When the heat-affected zone is a little large, it will cause serious deformation problems. However, the heat generated by the handheld laser welding machine during the entire welding process is low. Coupled with the relatively low thermal conductivity, high energy absorption rate and melting efficiency of stainless steel, well-formed, smooth and beautiful welds can be obtained after welding.

2. Carbon steel

Ordinary carbon steel can be welded directly by hand-held Fiber laser welding Machine, the effect is comparable to stainless steel welding, and the heat-affected zone is smaller, but when welding medium and high carbon steel, the residual temperature is relatively high, so it is still necessary to weld before welding. Preheating and heat preservation after welding to relieve stress and avoid cracks. Here we can talk about the cold welding machine. Medium and high carbon steel can be welded or repaired at a slow speed with cold welding and cast iron welding wire. In terms of temperature control, temperature control, and temperature control, the cold welding machine can teach hand-held laser welding more efficient on the heat residue after welding.

3. Die steel

It is suitable for welding various types of die steel, and the welding effect is very good.

4. Aluminum and aluminum alloy

Aluminum and aluminum alloys are highly reflective materials, and porosity may appear in the molten pool or at the root during welding. Compared with the previous metal materials, aluminum and aluminum alloys have higher requirements for parameters, but as long as the selected welding parameters are appropriate , the weld seam with the same mechanical properties as the base metal can be obtained.

5. Copper and copper alloy

The thermal conductivity of copper is very strong, and it is easy to cause incomplete penetration and partial fusion during welding. Usually, the copper material is heated during the welding process to assist welding. Here we are talking about thin copper materials. Hand-held laser welding Machine can directly Welding, because of its concentrated energy and fast welding speed, is less affected by the high thermal conductivity of copper.

6. Welding between dissimilar materials

The hand-held laser welding machine can be carried out between a variety of dissimilar metals, such as copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, low carbon steel-copper and other dissimilar metals. Laser welding can be carried out under any conditions (gas or temperature).

Handheld laser welding machine is currently a widely used product in the welding industry, mainly because although this equipment looks more expensive, it can save labor costs very well. The labor cost of welders is relatively expensive. Using this The product solves the problem of expensive and difficult recruitment of welders. Moreover, the handheld laser welding machine has won unanimous praise from thousands of customers due to its long service life and low energy consumption.

If you want to learn more about laser cleaning, or want to buy the best laser cleaning machine for you, please leave a message on our website and email us directly!

Post time: Dec-25-2024