As the saying goes, “Preparation is the key to success,” and this applies perfectly to the maintenance of laser cutting machines. A well-maintained laser cutting machine not only ensures smooth production but also extends its operational lifespan. It’s crucial to follow a detailed maintenance schedule that includes daily, weekly, and monthly tasks. Below are three basic yet vital maintenance precautions to keep in mind:

1. Routine Maintenance: Daily Care

Routine maintenance is the first line of defense in keeping your laser cutting machine running efficiently. Always begin by checking the protective lenses to ensure they are clean and free from contamination. If dirt or residue is present, use a soft cloth to gently clean the lenses. Never use abrasive materials, as they may scratch the surface. Damaged, scratched, or dirty lenses will affect the accuracy of the laser beam, leading to poor cutting performance.

Before starting the machine, always inspect the nozzle for any signs of damage or blockage. If the nozzle is damaged or clogged, it should be replaced immediately. Additionally, check the protective gas pressure and flow to ensure they are within the proper range. Performing a quick test to verify gas pressure and flow is also recommended.

2. Weekly Maintenance: Ensuring Optimal Functionality

Weekly maintenance ensures that your laser cutting machine remains in peak condition. Start by checking the chiller’s water level before turning on the machine. If the water level is low, top it up with distilled or purified water to maintain proper cooling performance. The chiller is responsible for controlling the temperature of the laser tube, which is critical for maintaining optimal machine performance.

During your weekly check, inspect the laser tube for any signs of wear or damage. If any issues are detected, replace the tube promptly to avoid any disruptions in production. Use a soft brush to remove any accumulated dust inside the machine, and ensure the machine stays dry and free from moisture.

3. Monthly Maintenance: Detailed Inspection and Lubrication

Monthly maintenance involves a more thorough inspection of the machine’s components. First, check the lubrication of the guide rails and screws. Ensure that the lubricant is clean, without any debris or blockages. Proper lubrication helps maintain smooth movement of the rails, ensuring accurate cutting and alignment of the laser beam.

It is also essential to disassemble the machine periodically and inspect each part for any signs of wear or potential damage. Any worn-out components should be replaced with high-quality parts to avoid future issues.

Conclusion

In summary, regular maintenance is key to ensuring your laser cutting machine operates at its best. Daily maintenance includes checking the lenses, nozzle, and gas pressure; weekly maintenance focuses on monitoring the chiller’s water level and cleaning the interior; and monthly maintenance involves inspecting and lubricating the guide rails and screws. Working with expert technicians and using high-quality replacement parts will help ensure your machine remains reliable for years.

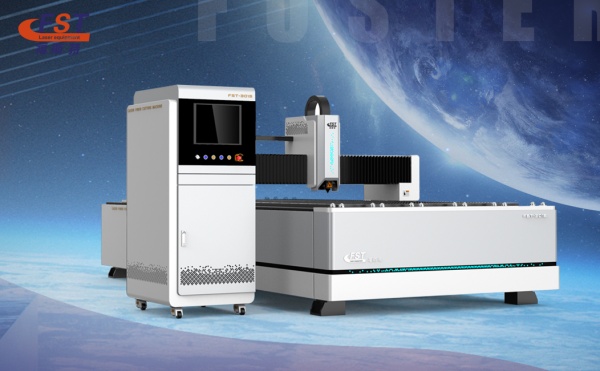

For companies like Liaocheng Foster Laser Science & Technology Co., Ltd., which specialize in laser equipment, ongoing innovation and service are just as important as quality maintenance. Established in 2004, Foster Laser is a leading manufacturer of high-performance laser equipment, including laser cutting machine , laser marking machine ,co2 laser engraving machine , fiber laser welding machine , and fiber laser cleaning machines. With over 20 years of experience, Foster Laser is committed to providing customized solutions and comprehensive after-sales support, helping businesses around the world enhance their production efficiency. Their products are CE and ROHS certified and are available with OEM options to meet various industrial needs. Whether you’re in need of laser equipment for metalworking, automotive, or other sectors, Foster Laser is dedicated to delivering exceptional products and services to ensure long-term success.

For more information on our products and services, feel free to contact us through our website or via email.

Post time: Jan-17-2025