Purchasing a laser welding machine for the first time can be overwhelming due to the variety of models and configurations available. To help you make an informed decision, this guide outlines the most important factors to consider when selecting the right laser welding machine for your needs.

Laser welding machines typically come with pulsed lasers or continuous wave lasers. Your choice depends on the material type and thickness you plan to weld.

Pulsed Lasers

Best for thin and light materials, such as sheet metal, razor blades, and gold jewelry chains.

Prevents deformation or melting of delicate parts.

Ideal for spot welding and precision tasks.

Continuous Wave (CW) Lasers

Suitable for thicker and heavier materials, including refractory metals.

Provides deep penetration and is effective for continuous welding applications.

Not recommended for very thin materials, as it may cause damage due to higher energy output.

If your application requires delicate detailing, go for a pulsed laser. For deep, continuous welds, choose a CW laser.

The laser power determines the welding depth and efficiency of the machine. Higher power levels are better suited for deep and continuous welding, while lower power levels work for shallow welds and spot welding.

· 1000W Laser Welding Machines – Suitable for 0.5mm–3mm welding depth and ideal for spot welding or penetration welding.

· 1500W–2000W Machines – Recommended for continuous welding of thicker metals requiring higher energy output and deeper welds.

For custom recommendations, Liaocheng Foster Laser offers free consultations to help determine the optimal power configuration for your application.

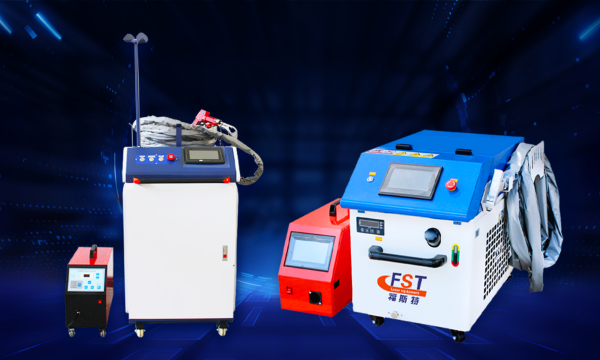

Laser welding machines come in various configurations to suit specific purposes. Consider your product type, processing technology, and requirements when selecting the right model.

Common Configurations

1.Mold Repair Welding Machines – Ideal for precision repairs on metal molds.

2.Handheld Fiber Laser Welding Machines – Flexible and easy-to-operate machines for large and irregular components.

3.Automatic Laser Welding Machines – Suitable for mass production and automation lines.

Multifunctional Models – Machines that combine welding, cleaning, and cutting in one device for cost-effectiveness and space-saving.

Choosing the right supplier is just as important as selecting the machine itself. A reputable supplier guarantees quality products, reliable support, and comprehensive training.

Liaocheng Foster Laser Science & Technology Co., Ltd. is a leading manufacturer with over 20 years of experience in laser technology. We offer:

Professional Training Programs – Ensuring you become an expert operator quickly.

Global Support – Serving over 100 countries with fast and efficient service.

Investing in a laser welding machine requires careful consideration of laser types, power levels, configurations, and supplier reliability. With the right machine, you can significantly enhance your production efficiency, product quality, and business growth.

Liaocheng Foster Laser Science & Technology Co., Ltd. provides high-performance laser welding solutions backed by expert training and after-sales support.

Contact us today to find the perfect laser welding machine for your needs!

Post time: Dec-23-2024