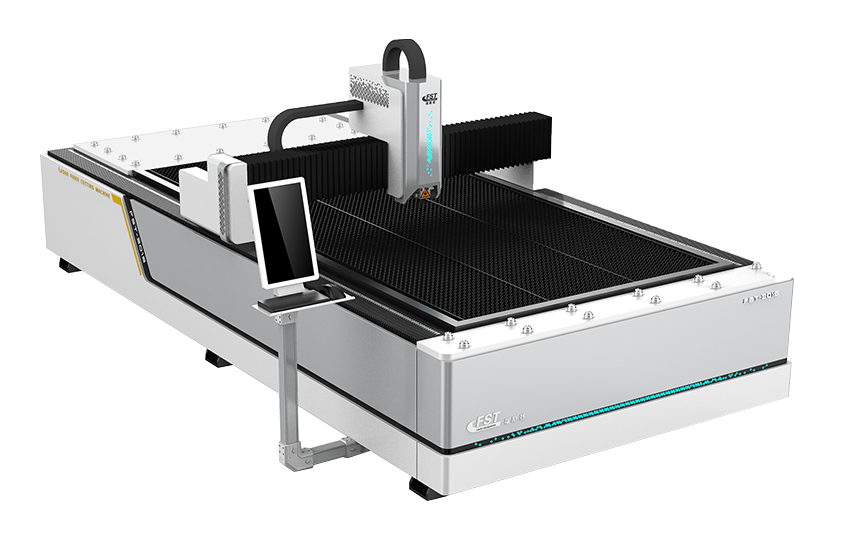

As industrial development rapidly progresses, fiber laser cutting machines have found widespread application. However, after prolonged use, the cutting accuracy of these machines may experience some deviations, resulting in products that may not meet the desired standards. These deviations are often caused by issues with the focal length. Therefore, it is crucial to understand how to calibrate the cutting accuracy of laser cutting machines. Here, we will explore the methods for adjusting the cutting accuracy of fiber laser cutting machines.

When the laser spot is adjusted to its smallest size, perform a spot test to establish the initial effect. The focal position can be determined by evaluating the size of the laser spot. Once the laser spot reaches its minimum size, this position represents the optimal processing focal length, and you can proceed with the machining process

In the initial stages of laser cutting machine calibration, you can use some test paper or scrap material to perform spot tests and determine the accuracy of the focal position. By adjusting the height of the laser head up and down, the size of the laser spot will vary during the spot tests. Repeated adjustments at different positions will help you identify the smallest laser spot, allowing you to determine the optimal focal length and the best position for the laser head.

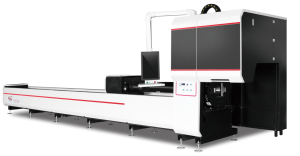

After the installation of the fiber laser cutting machine, a scribing device is mounted on the nozzle of the CNC cutting machine. This device is used to scribe a simulated cutting pattern, which is a 1-meter square with a circle of 1-meter diameter inscribed within it. Diagonal lines are scribed from the corners of the square. Once scribing is completed, measuring tools are used to verify whether the circle is tangent to the four sides of the square. The length of the square’s diagonals should be √2 meters, and the central axis of the circle should bisect the sides of the square. The points where the central axis intersects the square’s sides should be 0.5 meters from the corners of the square. By measuring the distance between the diagonals and the intersection points, the cutting accuracy of the equipment can be determined

Post time: Aug-20-2024