The advantages of 1000W, 1500W, 2000W, and 3000W fiber laser cleaning machines are as follows:

Non-Contact Cleaning: Laser cleaning is a non-contact method, avoiding mechanical damage to the surface, making it particularly suitable for cleaning fragile surfaces.

Environmentally Friendly: Laser cleaning typically eliminates the need for chemical solvents or large amounts of water, making it environmentally friendly and reducing waste disposal costs.

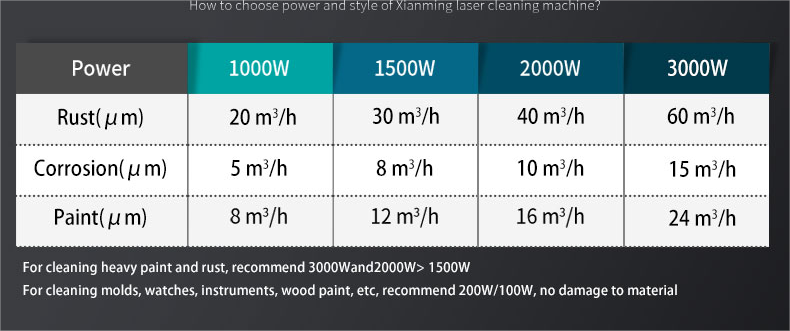

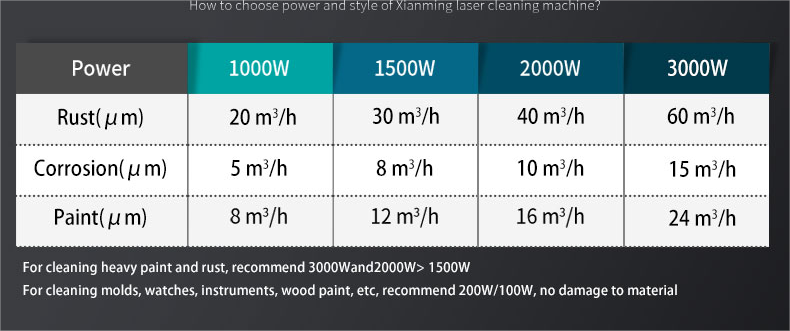

Efficient Cleaning:

- 1000W: Suitable for light dirt and surface coatings removal.

- 1500W: Offers higher cleaning speeds, effectively removing moderate levels of dirt and coatings.

- 2000W: Provides higher power for tackling more stubborn dirt and coatings.

- 3000W: Boasts the highest power, ideal for handling extremely stubborn dirt, oxidation, and paint.

Precision Control: Different power laser cleaning machines allow for precise control of the cleaning process by adjusting parameters to meet the requirements of various materials and contaminants.

High Energy Efficiency: Higher-power laser cleaning machines are generally more efficient, completing cleaning tasks in less time and reducing energy consumption.

Versatility: Laser cleaning machines ranging from 1000W to 3000W are suitable for various materials and industries, including metals, plastics, ceramics, electronics, aerospace, and more.

Please note that choosing the appropriate power level for a fiber laser cleaning machine depends on your specific application requirements. Higher-power machines are often more expensive but can handle more complex tasks. Therefore, the selection should be based on an assessment of the nature of the cleaning task, the material involved, and the scale of the operation.

Post time: Sep-16-2023