CypCut sheet cutting software is an indepth design for fiber laser cutting

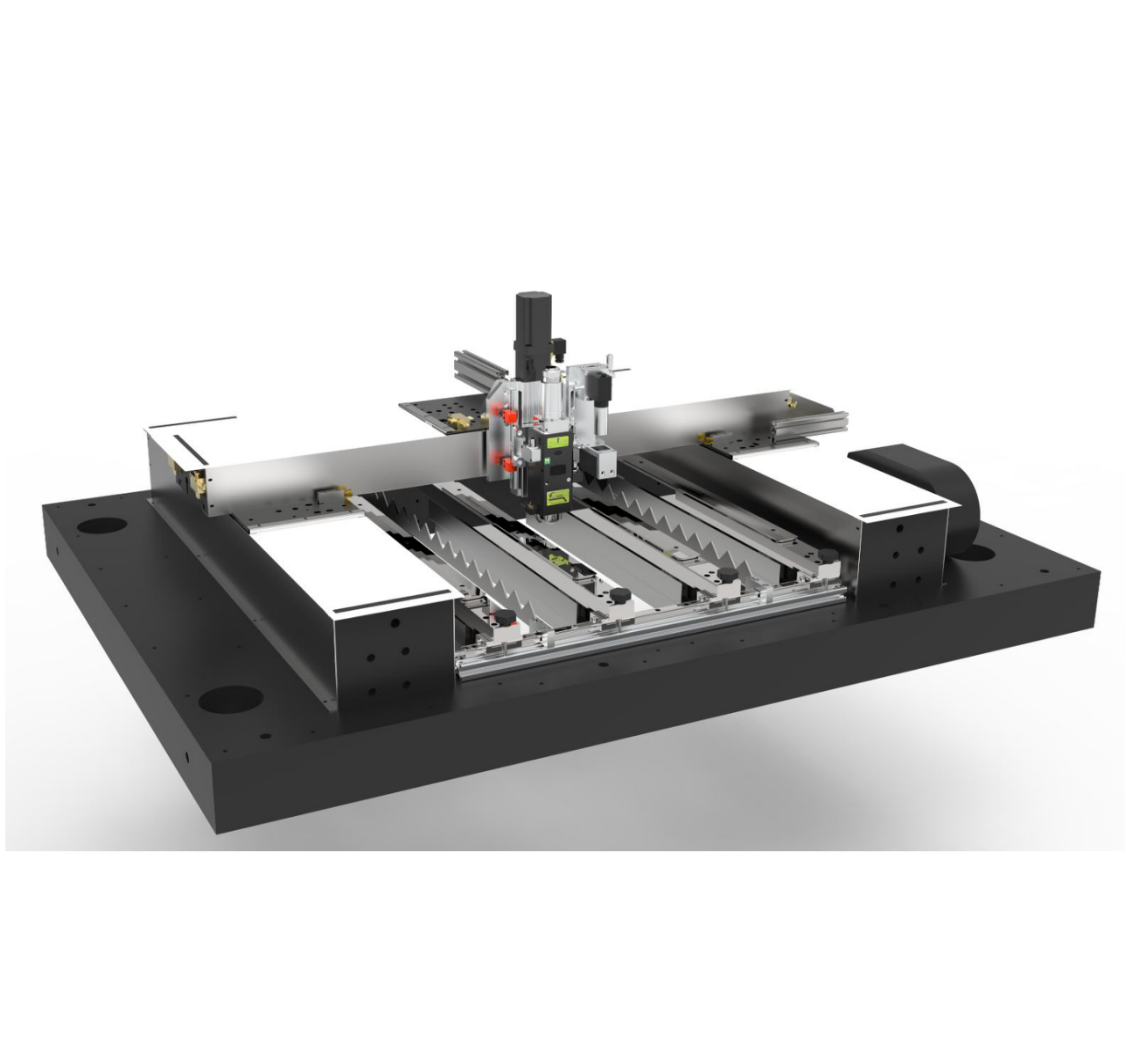

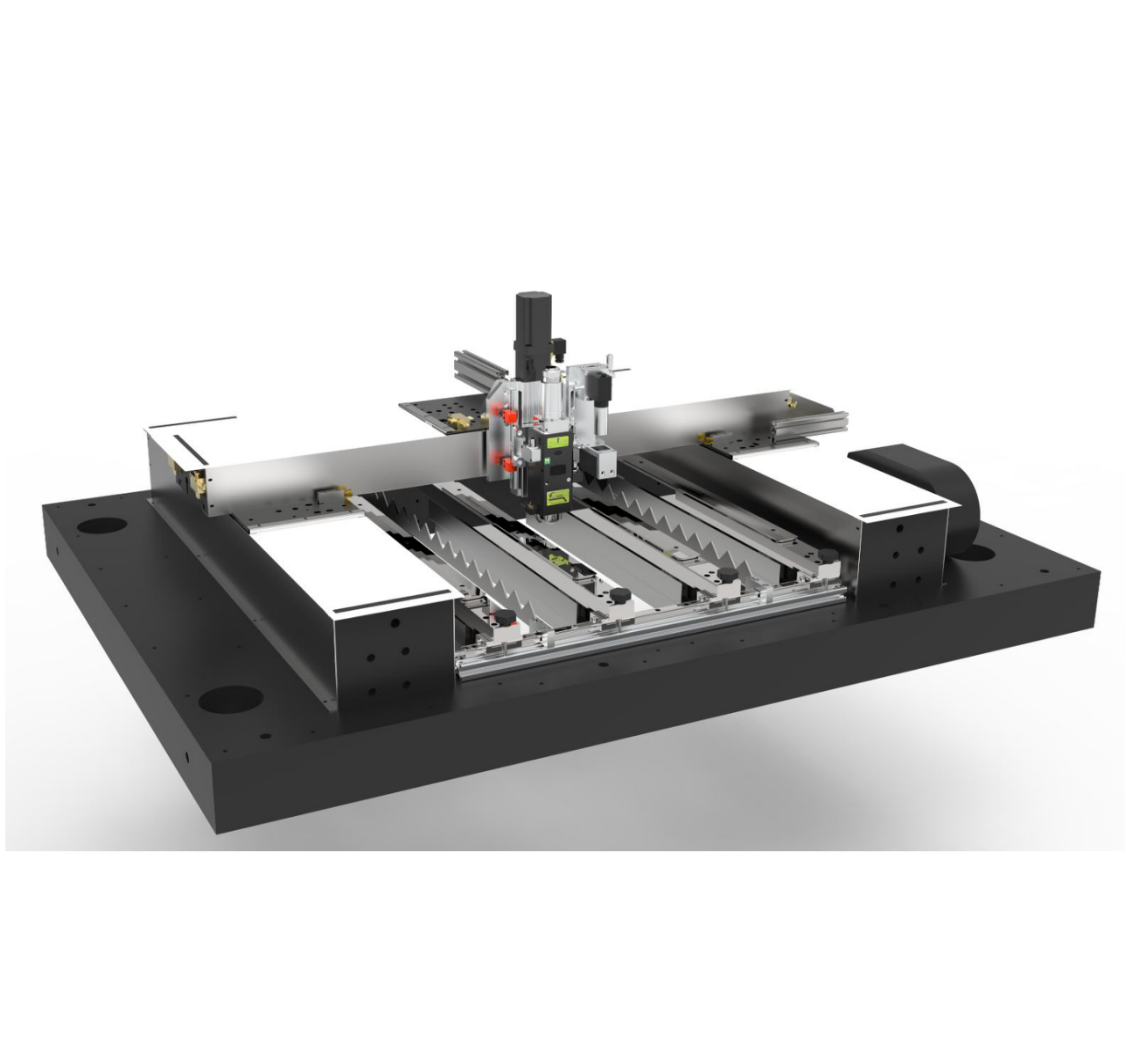

industry. It simplifies complex CNC

machine operation and integrates CAD,

Nest and CAM modules in one. From

drawing, nesting to workpiece cutting all

can be finished by a few clicks.

1. Auto Optimize Imported Drawing

2. Graphical Cutting Technique Setting

3. Flexible Production Mode

4. Statistic of Production

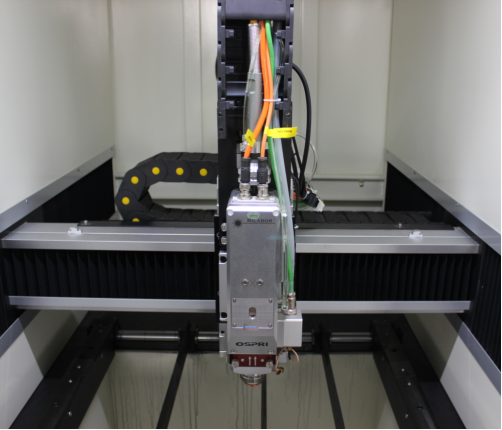

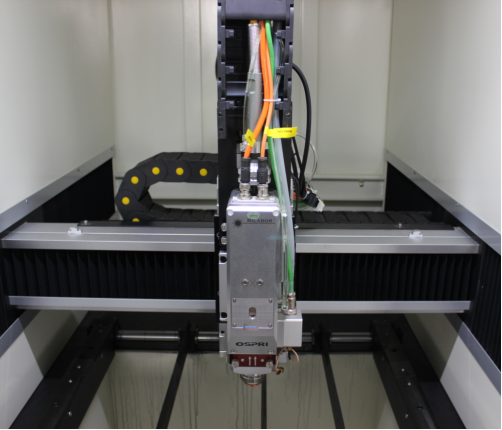

5. Precise Edge Finding

6. Dual-Drive Error Offset